- Insights & events

- Blog

Blog | July 11, 2024

Optimizing inventory allocation across networks to balance cost and service level fulfillment

Inventory costs directly contribute to product costs, making them a primary focus for supply chain professionals looking to reduce expenses in their distribution networks. In 4flow's global projects, we’ve found that inventory cost savings of 10% to 25% can be achieved by reducing overstocks and stockouts.

However, determining optimal inventory levels can be challenging. While reducing inventory can improve short-term cash flow, it may compromise supply chain performance and jeopardize customer service levels. This dilemma is particularly relevant for businesses managing physical goods in complex networks, especially those facing variable demand. Typically, these businesses include:

For such organizations, traditional inventory optimization might not suffice. To address their unique challenge, a network-wide approach is often required.

Let’s explore how network-wide inventory allocation optimization achieves this balance, beginning with common challenges in inventory management when demand is fluctuating.

Challenges of managing variable demand

Fluctuating demand makes it challenging to accurately predict future demand levels. This uncertainty can lead to inventory shortages or excess inventory, impacting customer service levels and operational efficiency.

Maintaining excess inventory during low-demand periods results in higher holding costs. Conversely, insufficient inventory during high-demand periods may lead to lost sales and missed revenue opportunities.

Different customer preferences, behaviors and policies might require an adaptable service level strategy – and create different cost levels.

Businesses with seasonal demand fluctuations must effectively manage seasonal inventory. This includes planning for inventory buildup before peak seasons and managing inventory liquidation strategies post-season to avoid excess stock.

When facing fluctuating demand, businesses may choose to hold less inventory and rely on expedited shipping to fulfill customer orders on time. The cost of expedited shipments can significantly impact profitability.

Optimal inventory allocation – an effective approach for a complex network

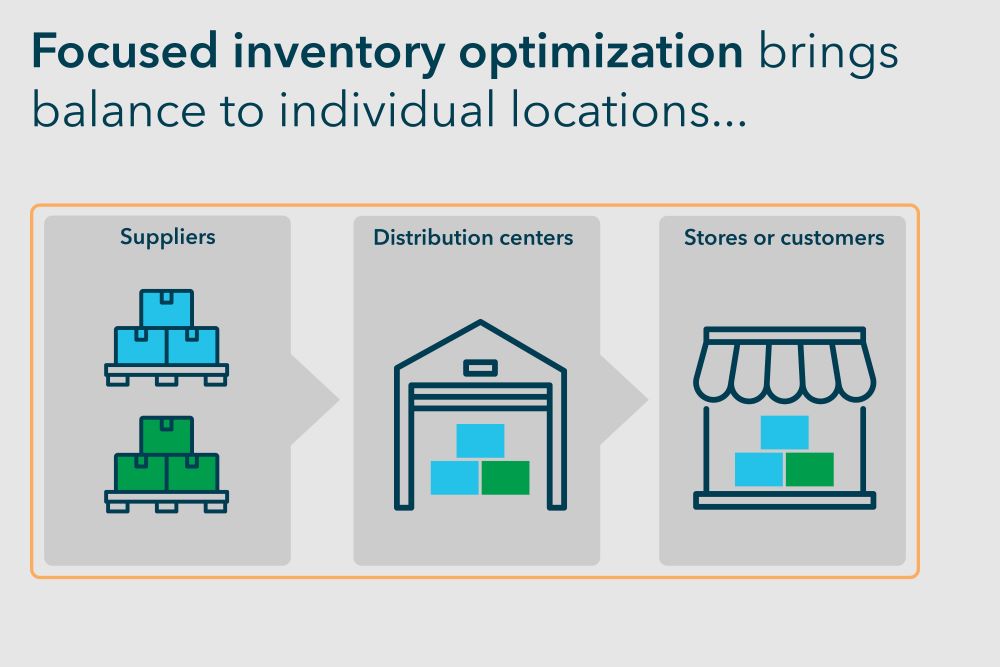

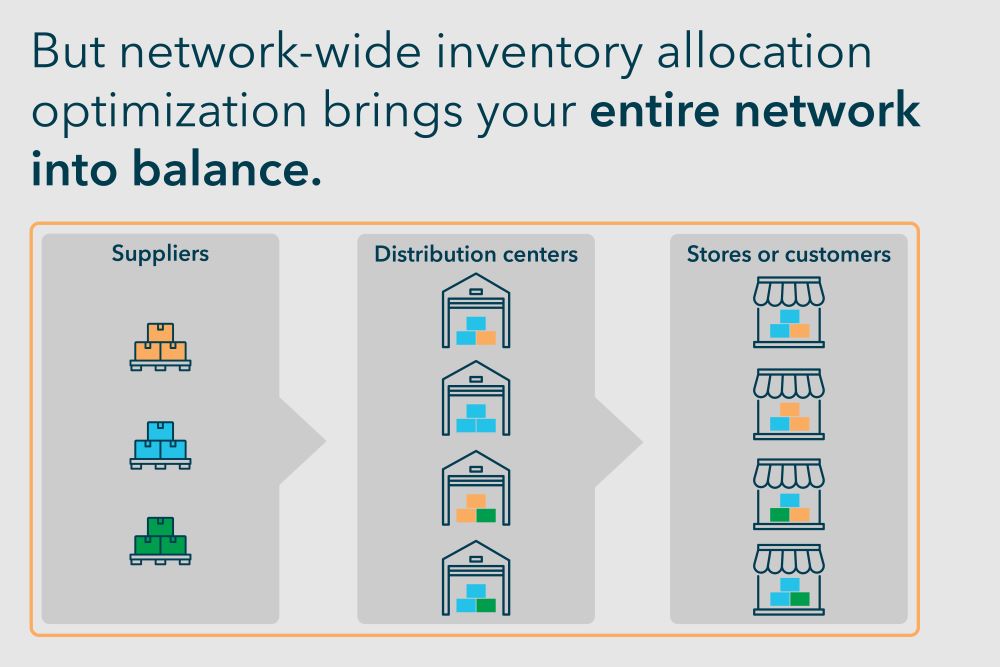

Inventory optimization focusing on individual locations might be familiar to many supply chain professionals. However, when it comes to the entire network, the approach needs to be more sophisticated to optimize inventory levels based on the interdependencies between different locations. This is where optimal inventory allocation comes in.

Inventory allocation is a systematic method of distributing inventory across various channels to optimize the fulfillment of customer orders. This strategic approach involves placing stock in warehouses, distribution centers or retail outlets across the network based on anticipated demand. By carefully allocating inventory, businesses can minimize storage and carrying costs while ensuring that products are readily available when customers place orders.

This process is crucial for businesses with complex networks as it enables them to:

-

Optimize stock levels across warehouses and distribution centers

-

Reduce inventory costs by minimizing excess inventory, storage costs and capital tied up in stock

-

Meet service level targets as it minimizes the distance products need to travel

-

Minimize sales losses or manufacturing delays by ensuring availability of products or components

-

Improve ability to meet customer demand thanks to efficient order fulfillment and mitigation of shortages

Imagine inventory optimization as optimizing the schedule and traffic for each station in a subway system individually. Optimizing inventory allocation would be like managing a subway system as a whole, so each station's schedule and traffic are optimized considering the overall network. Sound interesting?

First steps: actionable tips to start optimizing inventory allocation

1.

Start with an accurate demand forecast that draws on historical sales data, market trends and customer insights.

2.

Foster collaboration and communication between different departments involved in inventory management, such as sales, operations, and finance.

3.

Implementing inventory allocation optimization requires broad expertise. Determine if your organization has the necessary analytical capabilities to forecast demand, identify trends, patterns and opportunities for each product group. You’ll also need to align a strategy across the business, define performance metrics, optimize inventory policies, collaborate across functions, and manage change effectively. Dedicate an expert team or bring in external expertise to support the process.

4.

Consider dedicated software support designed to optimize inventory allocation and let your team concentrate on decision-making. Look for software that enables visibility, simulation and optimization.

5.

Conduct regular inventory audits to identify discrepancies, reduce shrinkage and improve allocation accuracy. This helps businesses maintain optimal stock levels and avoid overstock or stockouts.

Optimizing inventory allocation is an effective process that reflects the requirements of complex supply chains managing products with fluctuating demand. A network-wide approach enables businesses to distribute inventory efficiently and cost-effectively across warehouses, distribution centers and other sites – while meeting target service levels and ultimately enhancing customer satisfaction.

Author:

Andreas Martin

Director Software Quality & Support

4flow software