At 4flow management, we’ve consistently delivered remarkable improvements to our customers’ supply chains by helping to reduce transportation costs, boost network performance, and advance overall supply chain maturity.

In today’s rapidly evolving and competitive markets, however, transportation improvements alone are insufficient to reach high customer satisfaction levels and achieve the growth that is required.

By collaborating closely with our customers, we’ve identified opportunities to create even greater value by optimizing the entire supply chain for enhanced efficiency and resilience. We call this journey supply chain orchestration.

Author

Dave Salerno

Director

4flow management

The range of today’s supply chain challenges

The journey starts by listening to our customers about the challenges they face, whether it’s increased inventory levels or overstocking, for example. With the current interest rate, the cost of inventories has become even more expensive. This means that inventory management – or poor inventory management, to be more specific – has a significant impact on an organization’s profits and losses.

Furthermore, supply chain sustainability requirements across many industries are increasing. Whether government mandated, driven by shareholder expectations or ethics, this represents a significant challenge. In the automotive industry, for example, many businesses are currently struggling to stay ahead of the changes in OEM production plans for conventional combustion engines versus electric vehicles (EV).

Global disruption and high customer expectations

Compounding these challenges is the increasing frequency of global disruptions. Senior supply chain leaders often find themselves troubleshooting daily issues, leaving little time to focus on strategic initiatives. Many leaders today are seeing how difficult it is to manage a business when you're consumed by day-to-day operations.

Take, for example, the potential for work stoppages at US ports due to ongoing contract discussions. These recently threatened to disrupt supply chains and create shortages of essential goods. Not only can such disruptions impact domestic supply, but they also jeopardize international sales.

Another example: recent bankruptcies have led to significant resource shifts in supply chains. In cases like this, supply chain teams are often the last to know that products once sourced regionally need to come from overseas. As a result, these teams are forced to resort to air shipping until they can restore their ocean freight pipeline.

All of this happens amid increasing stakeholder expectations. What I call the "Amazon effect" has heightened expectations for real-time information and rapid decision-making, often relying on advanced technologies like AI. Despite technological advancements, the persistence of functional silos within organizations hampers collaboration, both internally and with external partners.

Enter supply chain orchestration

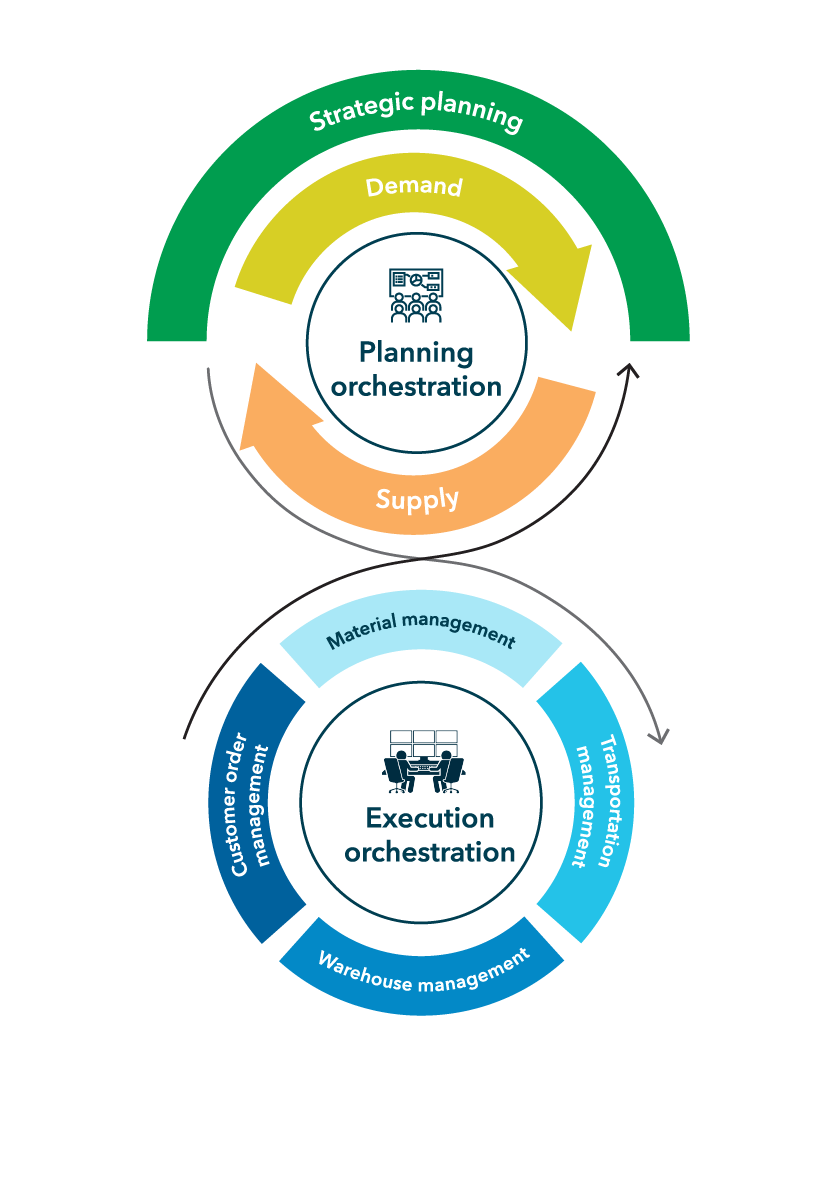

In the absence of a strong connection between supply chain planning and execution, supply chain orchestration reveals its benefits.

Supply chain orchestration is a framework for strategically coordinating and integrating all supply chain elements to ensure smooth, efficient and agile operations. Rather than focusing solely on transportation, supply chain orchestration involves overseeing the entire network. It aligns processes, stakeholders and technologies to optimize performance and enhance visibility.

By leveraging real-time data and advanced technologies, supply chain orchestration enables organizations to maximize efficiency, reduce costs, and bolster overall resilience, ultimately improving customer satisfaction.

At 4flow, we provide unparalleled support on the supply chain orchestration journey. Our highly customizable solution can be implemented across the entire supply chain or in specific segments, such as demand planning, inventory management, end-to-end supply chain execution, and beyond.

How to start the supply chain orchestration journey

To embark towards supply chain orchestration, organizations should begin by identifying their biggest pain points – whether it’s in demand planning, inventory management, or transportation. This assessment lays the groundwork for a maturity evaluation and helps to pinpoint existing resources and processes.

From this foundation, we can create a roadmap that emphasizes process improvement and the strategic use of technology.

What are the results of supply chain orchestration?

Through effective supply chain orchestration, organizations can unlock significant value, including:

Increased profitability and fewer lost sales

Reduced working capital: One 4flow customer decreased stock of high-value components by 5% through improved planning processes.

Enhanced customer satisfaction: Another customer reported a 10% improvement in order fill rates for their OEM service parts organization.

Achievement of sustainability targets: In early 2024, we completed a baseline carbon footprint assessment for our customers and integrated the data into their tracking systems. Now, they can assess the cost and carbon impact of their sourcing decisions.

At 4flow, we are committed to guiding our customers on their supply chain orchestration journey. To do this, we offer managed supply chain services, providing skilled teams and technology to support organizations throughout the process. Our consulting and software solutions are also tailored to meet customers’ specific needs and maturity levels. Together, we tackle the complexities of today’s supply chains to drive lasting improvements.