- Consulting

- Digital supply chain

- Artificial intelligence

4flow consulting

Artificial intelligence

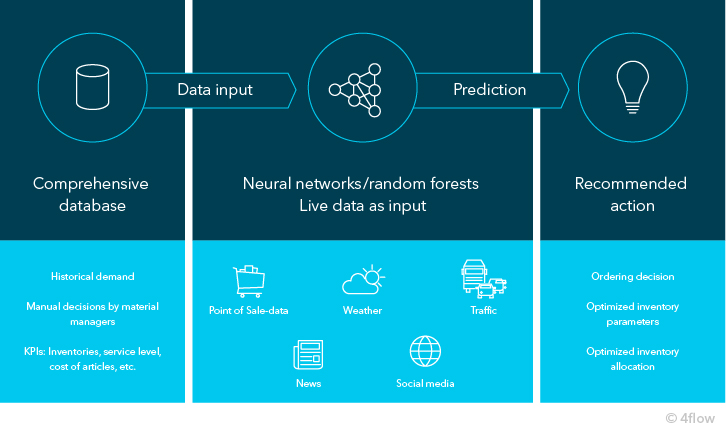

An increasing availability of data and networking of systems in the business environment provide a fundamental basis for the effective use of artificial intelligence (AI). With the help of advanced methods, algorithms for machine learning (ML) and predictive analytics are increasingly able to cope with amounts of data that are beyond the reach of humans and to recognize and process patterns independently. In this way, risks and requirements can be predicted with significantly improved accuracy as compared with conventional methods – helping to solve a variety of challenges in supply chain management.

Using AI, large amounts of data can be processed while patterns can be identified independently

Using AI, large amounts of data can be processed while patterns can be identified independently

With AI solutions in the supply chain, businesses gain significant advantages and opportunities for optimization, including:

- Increased transparency on processes and interdependencies

- Faster and more reliable forecasting for more efficient planning

- Increased service levels

- Risk prevention in the supply chain

- Improved utilization of resources

- Cost reduction and avoidance of costs

Using artificial intelligence efficiently with tailor-made solutions

4flow offers standardized approaches and methods to integrate machine learning algorithms (ML) into a business’s supply chain. The diverse range of applications include optimized resource management using precise, data-based demand forecasting – even with a high degree of variance – and inventory reduction through pattern recognition in customer order behavior.

In addition to improving processes and increasing efficiency and productivity while reducing and avoiding costs, the intelligent analysis of data and patterns along the entire supply chain makes it possible to recognize unseen relationships. Such opportunities can lead to the development of measures for future processes that will result in greater efficiency, agility and a lower risk of failure.

The use of artificial intelligence enables businesses to generate a competitive advantage in their existing environment and to sustainably optimize their value chains.

An overview of our services:

- Automation of business processes through independently acting AI

- Intelligent forecasting of required quantities for the optimization of material planning, transportation planning and sales management

- Identification of risk factors and event forecasting for the proactive management of global supply chains

- Increasing supply chain transparency through the integration of unknown external and internal process influences using AI pattern recognition and correlation analysis