- Consulting

- Logistics & production

- Layout planning & traffic concepts

4flow consulting

Layout planning & traffic concepts

Outdated structures, warehouse expansions or building plans that don’t consider existing conditions all share a common challenge: the need to determine optimal functional space locations in the layout and to develop an efficient traffic flow design. Overcoming this challenge requires taking all traffic routes, areas and users into account.

Currently, these supply chain challenges tend to result in competition for available space between the supply chain, production and other related areas. Instead of focusing on the overall optimum, this conflict leads to costly compromises for businesses. This tension can be avoided, however, through the development of an optimal layout and traffic concept early on.

Reaching the goal with concrete layout alternatives

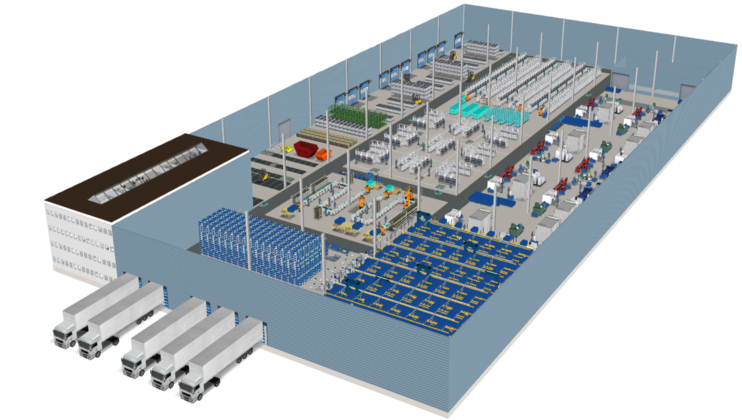

During layout planning, 4flow develops different scenarios based on lean supply chain design principles. With a combination of digital supply chain and lean management, customers can visualize and experience the different layout alternatives three-dimensionally. The optimal solution is then identified and developed in joint workshops.

At the same time, a coordinated traffic concept is developed and designed to maximize flow, synchronization and standardization. Using this new design, different route alternatives for traffic and concepts for scheduling time slots to compensate peak loads are determined.

Adjusting parameters during the planning process

During a project, initial parameters often change dynamically, especially for structures that have become outdated or in the case of plant or supply chain building expansions. For these instances of change, bottlenecks are identified and corresponding layout and traffic concepts are defined over different periods of time. In this way, staff, equipment and material flows can continue seamlessly throughout the project.

Leveraging simulations to optimize costs

In complex systems, bottlenecks are often difficult to identify and optimize. Event-oriented system simulation can help businesses to move beyond such impasses. The results of the simulation enable concrete strategies and actions to be developed and implemented. This leads to a significantly improved quality of results and a shorter project duration.

What 4flow offers:

- A cost-oriented, holistic planning approach for layout and traffic concepts

- Up to 25% reduction in required space

- Three-dimensionally visualized layout alternatives

- Lean processes

- Optimal space arrangement

- Synchronization with all traffic flows

- Scenario-oriented, flexible analysis

- Event-based simulation of complex systems